BelAZ 75710: The World’s Largest Haul Truck – Mind-Blowing Power & Engineering Feat

Introduction to the BelAZ 75710

The BelAZ 75710 is not just a truck—it’s the world’s largest mining dump truck, built to move mountains of earth and ore in a single load. Manufactured by BelAZ, a Belarusian company known for building ultra-heavy-duty mining vehicles, the 75710 is an icon of modern industrial strength. Built for open-pit mining, it has shattered world records and redefined what heavy equipment can accomplish.

The Story Behind Its Development

Founded in 1948, BelAZ has consistently produced mining vehicles for Soviet and later global markets. By the early 2010s, there was growing demand for super-capacity haulers to service the increasing productivity of mines across Russia, Australia, and South America.

Development of the 75710 Model

In 2013, the BelAZ 75710 was revealed as the crown jewel of the company’s lineup. Designed with input from mining corporations, it aimed to reduce the number of trips and optimize fuel consumption per ton.

BelAZ 75710 Record-Breaking Dimensions & Design

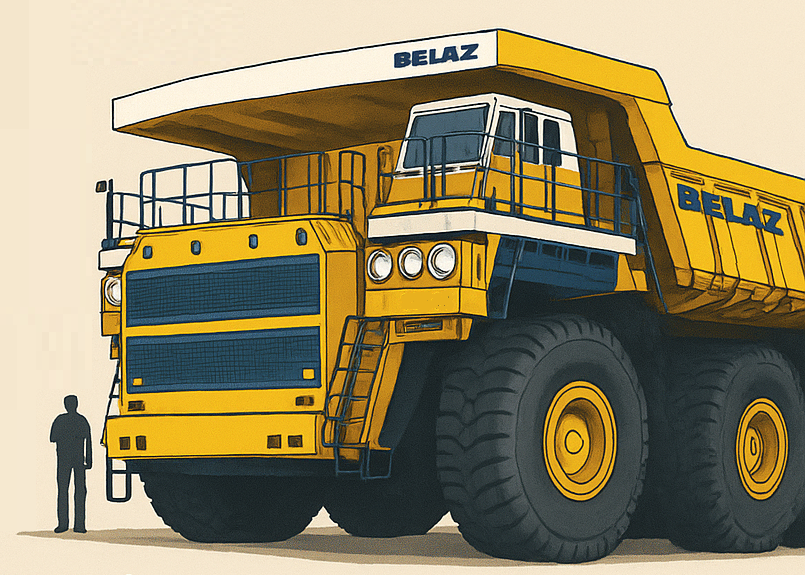

This mega truck doesn’t just impress with its power—it astounds with its physical presence.

This dump truck is so tall that a fully grown man barely reaches halfway up the tire.

Physical Dimensions

| Spec | BelAZ 75710 |

|---|---|

| Length | 20.8 meters (68.2 feet) |

| Width | 9.75 meters (32 feet) |

| Height | 8.17 meters (26.8 feet) |

| Curb Weight | 360,000 kg (795,870 lbs) |

| Max Payload | 450 metric tons |

| Tires | 8 x 59/80R63 low-pressure |

It’s longer than two buses and taller than a two-story house.

Unique Design Elements

With two front and two rear axles, the BelAZ 75710 offers better weight distribution. Its frame supports extreme pressure without bending, even when fully loaded.

Comparisons to Other Haul Trucks

Compared to the Caterpillar 797F or Komatsu 980E-4, the BelAZ 75710 outperforms in nearly every physical and payload specification.

BelAZ 75710 Powertrain and Performance Capabilities

One of the most groundbreaking features of the BelAZ 75710 is its dual-engine powertrain:

Dual-Engine System

It packs two 65-liter V16 diesel engines, each generating 2,300 horsepower. Combined, that’s 4,600 horsepower—enough to power a small town.

- Two 65-liter diesel engines

- Combined output: 4,600 horsepower

- Uses electronic synchronization for balanced load distribution

Additional Innovations:

- Stair-accessible cab for driver safety

- Electronically controlled suspension

- Heavy-duty steel chassis designed for maximum stress absorption

Transmission Specs

Each engine powers a separate generator that feeds into AC traction motors located at each axle. This diesel-electric transmission ensures smooth torque even under max load.

Fuel Efficiency vs Power

Despite its size, the 75710 is engineered for optimal fuel use per ton moved, making it surprisingly efficient in large-scale mining.

BelAZ 75710 Payload and Carrying Capacity

The BelAZ 75710 isn’t just large—it’s the heaviest lifter in the industry.

Maximum Payload Stats

It can carry up to 450 metric tons (496 U.S. tons) in a single load—over twice the capacity of some competitors.

Comparison with Competitors

| Model | Max Payload (tons) | Horsepower |

|---|---|---|

| BelAZ 75710 | 450 | 4,600 |

| CAT 797F | 400 | 4,000 |

| Komatsu 980E-4 | 360 | 3,500 |

Impact on Mining Productivity

Higher payload = fewer trips = lower costs. Mining operations report productivity boosts of up to 25% after switching to the BelAZ 75710.

Despite its size, it offers a relatively efficient liters-per-ton-kilometer ratio, improving long-term operating costs for mining corporations.

BelAZ 75710 Tires and Chassis Engineering

Engineering a truck of this magnitude requires innovation from the ground up—quite literally.

Custom-Made Tire Systems

The BelAZ 75710 rides on eight massive Michelin radial tires, each standing nearly 4 meters (13 feet) tall. These specialized tires are custom-built to endure over 100 tons of pressure per wheel, maintaining grip and durability in extreme mining environments.

Suspension and Load Distribution

The truck features an independent hydropneumatic suspension system, ensuring optimal shock absorption. Its weight is balanced across all four axles, a rare feat that prevents frame stress and increases longevity even under the harshest conditions.

BelAZ 75710 Technological Innovations

This truck isn’t just a brute—it’s intelligent, too.

Onboard Systems and Automation

The BelAZ 75710 is fitted with real-time load monitoring, automated brake systems, and drive diagnostics. It can even communicate directly with centralized mine control systems to coordinate haul routes and avoid collisions.

Safety Features

It includes collision avoidance systems, anti-lock braking, fire suppression systems, and multiple emergency stop switches. Cabin ergonomics also reduce operator fatigue, with climate control and air-filtration systems for dusty conditions.

GPS and Telematics

GPS-linked telematics systems allow for fleet tracking, route optimization, and performance diagnostics—all accessible remotely from a control center.

Environmental Impact and Efficiency

Despite its colossal size, the BelAZ 75710 aims for reduced ecological footprint.

Emission Standards

Both diesel engines comply with EU Stage I and Tier 1 emission standards, a notable achievement for a truck of this scale.

Noise and Fuel Impact

Soundproofing measures reduce operational noise, and the diesel-electric hybrid system helps optimize fuel usage—critical in long-haul mining.

Green Tech Considerations

BelAZ is actively researching electric drive technologies and renewable fuel integration to make future models even more sustainable.

Challenges in Operating the BelAZ 75710

Running this massive machine isn’t as easy as turning a key.

Training and Crew Requirements

Operators must undergo specialized training, often lasting several weeks. Crew teams also include dedicated mechanics, electronics specialists, and tire experts.

Terrain Limitations

The BelAZ 75710 requires wide, stable haul roads. It’s best suited for open-pit mines with heavy-duty infrastructure—not narrow or steep routes.

Maintenance Complexities

Routine maintenance involves a dedicated bay, cranes, and diagnostic software. Each tire change, for instance, can take several hours and specialized lifting rigs.

Manufacturing Process and Production

Behind the 75710’s brute strength is a team of brilliant engineers.

Where It’s Built

Every BelAZ 75710 is assembled at the Zhodzina plant in Belarus, a facility with over 60 years of experience in heavy machinery.

Engineering Teams Behind It

Collaborating with global firms like Siemens (for electric components), BelAZ engineers design every component to withstand decades of mining use.

Production Volume

Due to its complexity and cost, only a few dozen units have been produced and deployed worldwide since its debut.

Cost of the BelAZ 75710

Unsurprisingly, this world-record truck doesn’t come cheap.

Purchase Price

The average cost of a single BelAZ 75710 is around $6–7.5 million USD, depending on configuration and client requirements.

Operational Costs

Fuel, tire replacement, maintenance crew salaries, and insurance contribute to an estimated $1 million annual running cost.

Total Cost of Ownership

With a lifespan of 15–20 years, total ownership costs can exceed $20 million USD, although the ROI through improved haul productivity justifies the investment for many mining companies.

Global Deployments and Real-World Usage

The BelAZ 75710 isn’t just a prototype—it’s working around the world.

Mines Using the 75710

- Kuznetsk Basin, Russia

- Ekibastuz Coal Mine, Kazakhstan

- Siberian Ural Mines

Case Studies

In Kazakhstan, the introduction of the BelAZ 75710 reduced fleet sizes by 30% while increasing ore output by 18%.

Performance Reports

Operators report excellent reliability, provided maintenance schedules are closely followed. Fuel efficiency gains have also been noted compared to older, smaller fleets.

The Future of Ultra-Class Haul Trucks

With mining technology evolving rapidly, what’s next?

Trends in Electric & Hybrid Haul Trucks

Companies are exploring full-electric haul trucks and hydrogen-powered models to cut emissions and reduce operational costs.

BelAZ’s Next-Gen Roadmap

BelAZ is reportedly developing a fully autonomous haul truck and electric-powered prototypes, aligning with global green mining initiatives.

Engineering Marvel or Marketing Giant?

There’s debate around whether the BelAZ 75710 is truly practical or mostly symbolic.

Criticisms and Praise

Critics argue the size adds complexity, while proponents point to its unparalleled efficiency and reduced fleet size needs.

ROI and Real-World Results

In many mines, the BelAZ 75710 has delivered double-digit productivity increases, justifying its size and cost.

Comparison with Caterpillar 797F and Komatsu 980E-4

Let’s see how it stacks up against other giants.

| Specification | BelAZ 75710 | CAT 797F | Komatsu 980E-4 |

|---|---|---|---|

| Max Payload | 450 tons | 400 tons | 362 tons |

| Horsepower | 4,600 HP | 3,790 HP | 3,500 HP |

| Top Speed | 64 km/h | 68 km/h | 64 km/h |

| Operating Weight | 840 tons | 623 tons | 625 tons |

The BelAZ 75710 leads in payload and engine power, though CAT and Komatsu offer greater speed and lower operational complexity.

Media and Pop Culture Appearances

Not surprisingly, this truck has become a symbol of engineering excess.

Documentaries

It has featured in several shows including Mega Machines and Extreme Engineering.

Social Media Fame

From TikTok to YouTube, videos of the BelAZ 75710 draw millions of views, often comparing its size to airplanes and football fields.

Engineering Expos

It’s a star attraction at Bauma and MINExpo, where enthusiasts flock to get a glimpse of this mechanical marvel.

Frequently Asked Questions About BelAZ 75710 (FAQs)

1. What is the BelAZ 75710 used for?

It’s used in large open-pit mining operations to transport massive loads of earth, ore, and rock.

2. How fast can the BelAZ 75710 go?

Its top speed is approximately 64 km/h (40 mph) when unloaded.

3. Where is the BelAZ 75710 made?

It is manufactured in Zhodzina, Belarus, by BelAZ.

4. How much fuel does the BelAZ 75710 consume?

Fuel consumption is roughly 1,300 liters per 100 km, depending on load and terrain.

5. Can it be driven on public roads?

No. Its size and weight make it illegal for road use; it operates only within mine sites.

6. How many BelAZ 75710 trucks exist?

As of now, only a limited number have been produced, estimated to be less than 50.

Conclusion

The BelAZ 75710: The World’s Largest Haul Truck is a true icon of industrial power, engineered to meet the growing demands of modern mining. Its unmatched payload capacity, innovative dual-engine system, and advanced tech make it not just a mechanical marvel but a productivity powerhouse. While not without challenges, its presence in the mining world sets a new standard for what’s possible in ultra-heavy haulage.